You need to feel confident in your blister card packaging solution.

Our lineup of unit and multi-dose medication blister card packaging systems offer a safe and efficient method for packaging, verifying, and dispensing medications. With user-friendly design and space-saving features, these innovative systems simplify the medication administration process, ensuring accuracy, convenience, and peace of mind. Explore further to learn more about how our blister card packaging systems can revolutionize medication management for both pharmacy technicians and caregivers alike.

NB 200

Features

Efficient

Streamline your blister card production with in-line packaging and verification in one powerful solution

High Capacity

Holds up to 200 hot-swappable medication cartridges for access to a virtually unlimited formulary

Flexible

Built-in manual dispensing allows an operator to quickly and easily insert one-off orders into the workflow

Traceability

Follow medications and patients throughout the process, including repacking with a full evidence trail

Versatilty

Work with most major card providers and easily offer both unit-dose or multi-dose based on the needs of your facilities.

NB200 Overview

Meet The LittleBots

Noritsu is excited to offer a new, cutting-edge family of compact, efficient, reliable, and affordable compliance packaging solutions. Our LittleBots bring all the advantages of automation to your workflow, without the complexity and costs of full-scale systems.

Consisting of three units, the LittleBot family is tailored for scalability and growth, empowering pharmacies of all sizes to improve their efficiency without extensive software or labor investments.

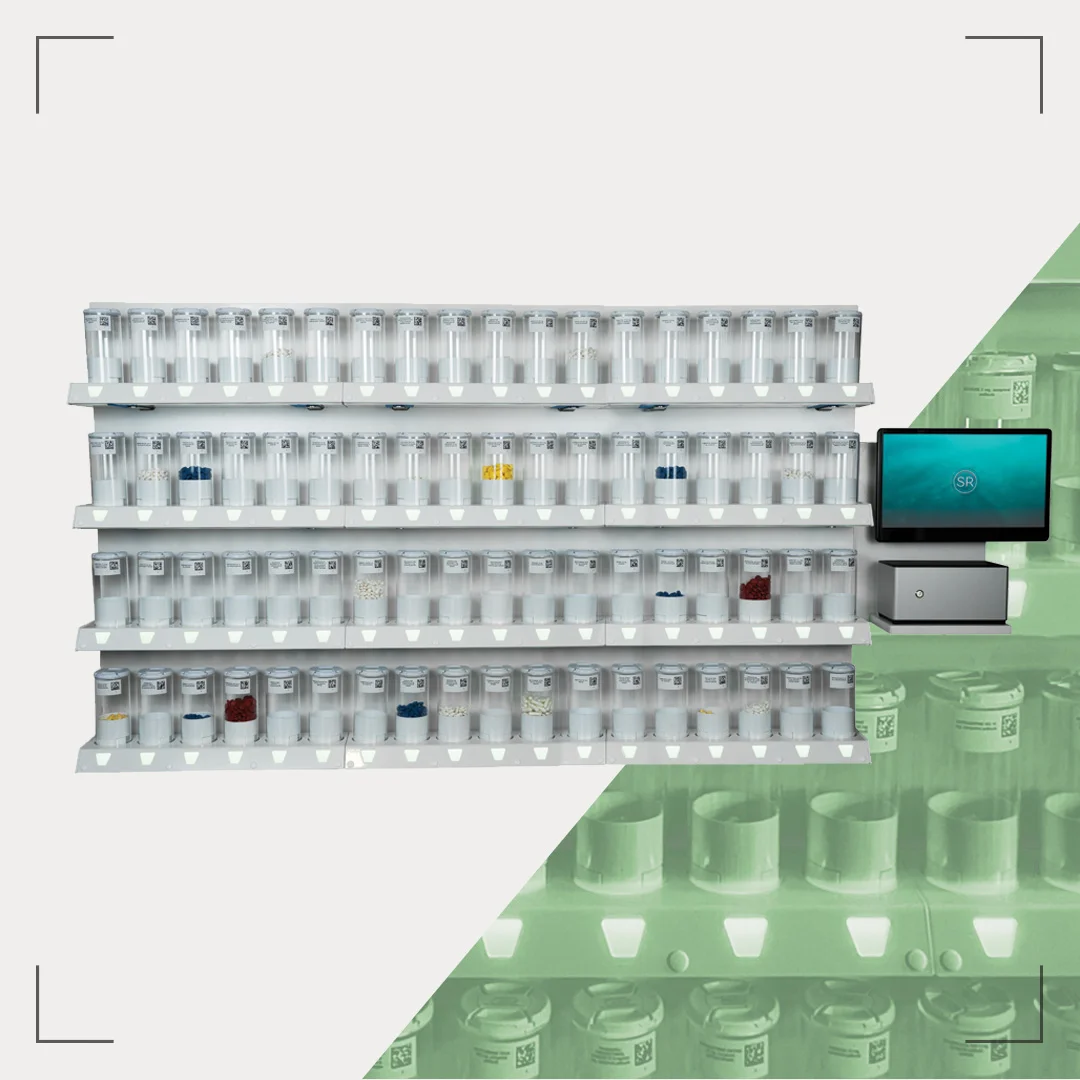

LARS

Scalable Light-Assisted Rack System

- Streamline your production with space for up to 386 extra canisters or 64 modules

- Intelligent smart rack technology quickly identifies the appropriate canister from your formulary for easy exchanges

- Add unlimited canisters, SR Controllers, and Rack Modules for continuous growth and scalability

- LARS can link across multiple Celia units

creating a synchronized and highly efficient operation that grows with you