How Do You Support High-Volume Centralized Prescription Fulfillment?

By delivering automated packaging, verification, and workflow solutions designed to handle fluctuating prescription volumes while maintaining accuracy, consistency, and throughput.

Highly controlled, high-volume fulfillment operations rely on integrated automation and verification to ensure reliable performance, reduce manual touchpoints, and support repeatable, scalable workflows.

Challenges for Central Fill Pharmacie

Recommended Solutions

Automation designed for repeatable performance at scale, purpose-built for high-volume centralized fulfillment environments.

Packagers

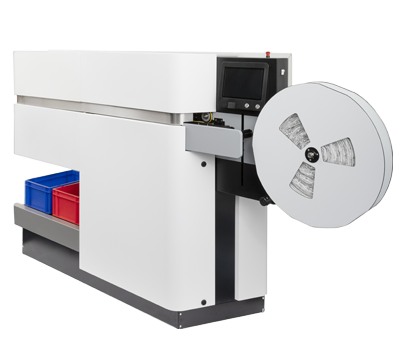

NX400

High-Capacity Strip pouch packaging engineered for the most demanding pharmacies

- Dispense up to 55 pouches/min

- 400 Active cassettes slots

- Best for high-volume

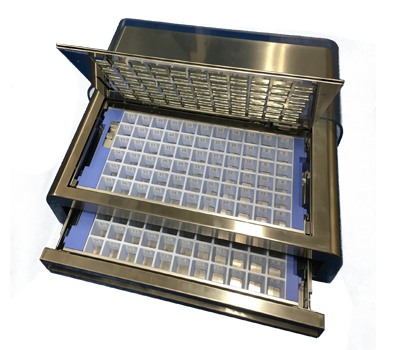

NB200

High-Capacity Strip pouch packaging engineered for the most demanding pharmacies

- Process up to 40 trays per hour

- All-in on packaging, verification, and archiving

- Compatible with nearly all blister card types

NexusRxUnify your PMS, packaging, and verification - Any model, any modality, any location.

- Compatible with all major PMS systems

- Workflow analytics for increased efficiency

- Manage multiple systems from one location

Medication Verifiers

NVPRO

Image, verify, cut, and roll orders based on your criteria, all in one pass

- Process and sort up to 180 pouches/min

- Create a traceable archive of every pouch

- Best for high volume, multi-location production

NV2

Quickly and accurately image, verify, and archive every pouch

- Image and verify up to 75 pouches/min

- Mid-size verification solution

- Best for high volume production in a smaller space

NVCore

Pouch verification with a desktop footprint

- Image and verify up to 90 pouches/min

- Desktop Verification solution

- Best for Retail /Combo and independent operations

Accessories

Benjamin

Pre-load trays with lesser-used meds that fit seamlessly into production

- Easy to follow fill-by-light loading

- RFID encoded trays ensure accuracy

- Trays can be swapped between multiple packagers

Blade Pill Splitter

Quick and precise pill splitting that generates less dust than competitive products

- Fits on a desktop

- Compatible with NX series cassettes

- Precision cuts mean less waste

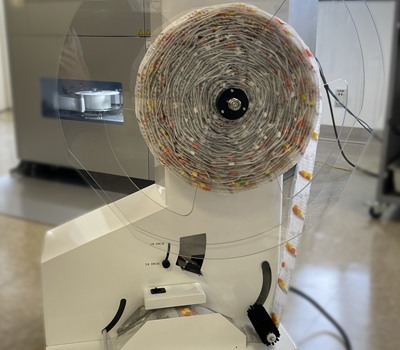

PW-1 Winder

Modular rack winding system for strip pouch rolls

- Adjustable motor-driven winder

- Easily transfer rolls from packager to verifier

- Scalable, add more reels or units as needed

Key Benefits for Central Fill Pharmacies

-

Accuracy & Quality Control

Packaging and verification solutions support consistent, repeatable processes that help maintain accuracy across high-volume fulfillment operations.

-

Throughput & Operational Efficiency

Automated workflows enable central fill pharmacies to process large prescription volumes while maintaining reliable, predictable turnaround times.

-

Workflow Integration & Scalability

Solutions are designed to integrate with enterprise systems and support standardized, scalable workflows as fulfillment volumes grow.